DRILLING THE EASTERN GOLDFIELDS OF WESTERN AUSTRALIA

An estimated 100 million ounces of gold has been calculated in terms of production, resources and reserves in the Eastern Goldfields of Western Australia. With the price of gold on the rise and the global demand reaching 1290 tonnes in the first quarter of 2016, up 21% on last year, there’s seems to be no better time than the present to be involved in the gold industry!

EXPLORATION

Recently there has been numerous announcements of new exploration targets around the district, you would think after a century of gold mining the Eastern Goldfields would be starved of its name sake resource! With an estimated 500,000 drill holes sunk in the region over the century, 480,000 recorded by Placer Dome in 2004, there are still ongoing explorations yielding results that encourage investment. With the technological advances of modern exploration there are plenty of resources available to identify the geology of mines. Collating core sheets, old reports and re logging them along with new exploration findings will allow for a transparent and cohesive database for your explorations projects.

PROVING

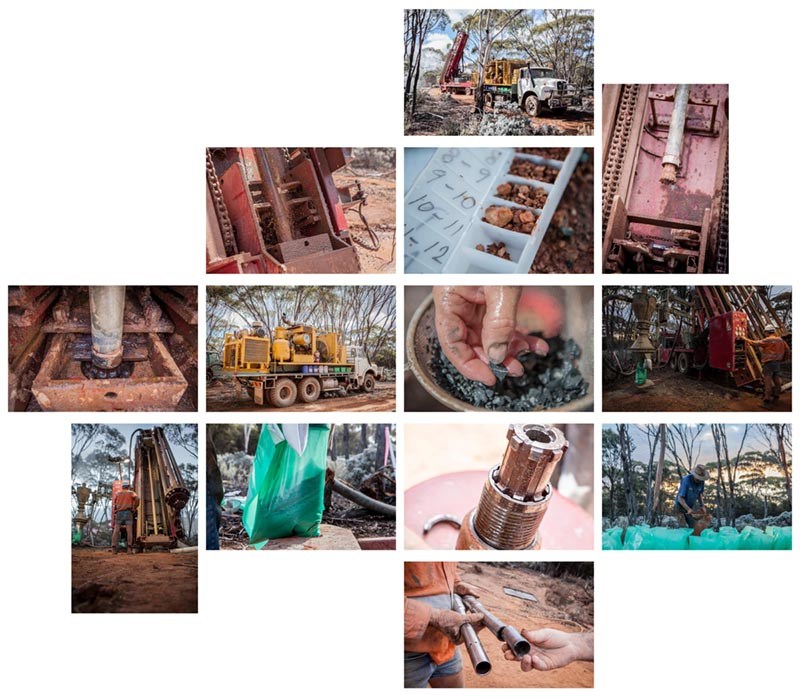

We are frequently reminded of the large-scale mining projects; with the current ideal market conditions the small scale gold miners who have been biding their time are now more active and prevalent. How do they get their mine to the stage of becoming a viable mine site? A recent field trip to a small prospect in the Eastern Goldfields allowed Worthy Parts to find out more about the stages from pegging to proving a mine site.

RESULTS

Initial stages a sampling program using an auger as a means of collection is implemented to identify geochemical variations. The method of an Auger program allows for the collection of samples that identify if the three meters surface of a lease contains samples of gold or related pathfinder elements once assayed. If evidence of a quantifiable precious metal is collected a diamond drill plan is developed in which a solid core is extracted from depth for examination on the surface. This process allows geologists to identify and map the rock formations to a depth as much as 1000meters. Pending on the results the next stage is to implement Reverse Cycle (RC) Drill plan which produces dry rock chips. Once these processes are completed mine owners are able to adept to costings and implement a mine plan. It’s this critical point where a mines weight of gold can be established and further investment can be procured to pursue extraction plan the mines life expectancy.